After Long Silence

With only two posts in the last nine months I thought it was time to make provide another missive as proof of my continuing existence…

I’ve been toying with an idea, likely never to make it into the material world, but fun nonetheless:

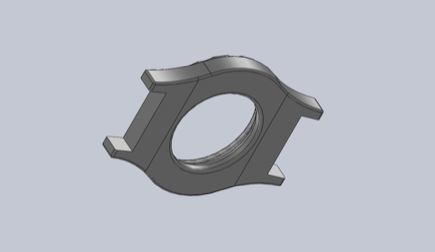

The “faceless watch”, an idea I haven’t seen before. With a ring of LEDs à la Tokyoflash behind the plastic ring crystal. The big problem obviously is the battery- it can’t go anywhere inside the watch, it would need to be on the other side of the band somewhere, maybe as part of the clasp with electrical wires running to the watch. Electronics layout would be a challenge but I think surmountable, with tiny MLF package ICs and multilayer PCB. The proportions and dimensions as I skeched them may not be possible, but something like it would probably work.

It would certainly be a challenge to construct- from a circuit design, software design, mechanical design and machining stand-point.

100 LEDs, 16 Square Inches

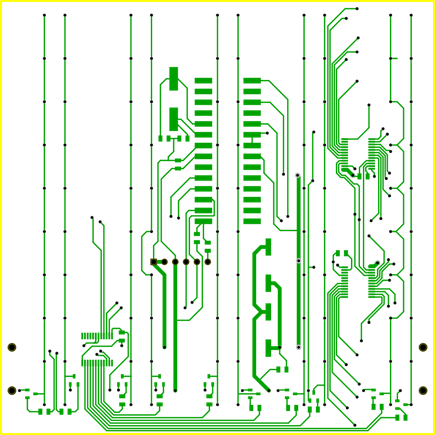

I wrote about a project back in August that I called the Twinkle Tag, as an experiment in PCB design and construction- seeing if I could fit 100 RGB LEDs, plus all the circuitry required to drive them in a scanning array based off the Peggy 2 from EMSL on a four inch square two-layer board. When I wrote the last post in August I had finished that design and had sent it out to Sure Electronics’s PCB fabrication service.

Forward to September. After around six weeks of waiting the PCBs finally show up from China. Where I purchased five boards, they sent eight. The quality of the fabrication looks alright. Clean routed edges are nice. A couple of boards look somewhat more suspect than others, with visible score marks. I assembled all the support components on one board and pulled a few PLCC-6 RGB LEDs off a short piece of flexible LED tape I bought a long time ago from DealExtreme. Quickly I noticed a few problems with the board layout- the most glaring of which is in the front side LED array- there are traces connecting sets of three horizontal rows vertically at the pads of the LED- it appears that the vertical traces that make up the column connections in the grid (on the positive side of the LEDs) were copied onto the pads on the row (negative) side of the LEDs. As well, one of the rows was missing a trace connecting it to the LED driver chip, rendering it dark. After a fair bit of meticulous rework with a dremel cutting blade and soldering small wire bridges the basic functionality was confirmed with the Peggy 2 demo programs. I had put off ordering enough LEDs- more were ordered shortly after receiving the boards.

In Search Of Cheap Fast

Since last time’s disappointment with the performance of the “Alt-Kart” set up with Mars BLDC motor and malfunctioning (now dead) Sevcon PMAC controller it’s been on my summer list to make the kart fast- not perfect, just cheap dirty and fast. To that effect, and to celebrate the ending of summer vacation (classes start tomorrow, Monday) Micah and I got together on Friday to make it happen.

Twinkle Tag: An SMD Experiment- Part 1, Design

I’ve designed and had manufactured several PCBs over the last couple years for the Battery Regulator project. I’ve focused on using through-hole parts, using surface mount components infrequently only when necessary. Even after spending hours condensing the components and finding clever ways to rout traces to maximize the use of board- space I find the design rarely looks particularly dense or crammed. SMD parts to the rescue-

This project was conceived as a challenge, not out of necessity. I wondered if I could condense the circuitry required to drive a 10×10 RGB LED matrix (based on the EMSL Peggy 2 schematic) onto a small single two-sided circuit card, with no wasted space around the edges. This presented a couple challenges. I routed all the row circuitry horizontally on the front of the board, but since the row traces must be unbroken, all the column traces must be on the back of the board, attached via vias. This means the only space for support circuitry was between the ten column traces. Grouping the column traces in sets of two leaves four wider open strips, but only connectible to each other horizontally between the rows of LEDs on the front of the board. I was truly interested to see if it was possible to fit all the required connections or if I would run into insurmountable routing puzzles. About ten hours later I had drawn up all the footprints and traces- it looks like it’s not an impossible problem at all- it actually went together pretty elegantly.

Now the real question- to build it or not. I suppose the corillary to the “design a tricky high-density SMD based board” challenge is “assemble that tricky high-density SMD based board”. And of course, besides being a soldering challenge, it would be a pretty nifty little widget if it does in fact work. I’ve taken it as an opportunity to try out Sure Electronics‘s seriously cheap PCB fab service. (search eBay to find it) Depending on how long it actually takes to get these boards and their quality once they get here their service could be a really excellent bargain. Then it’ll be to Digi-Key for a bounty of 0805 passives, SOT-23 transistors and TSSOP-24 ICs. And to eBay for a bulk pack of “5050” or “PLCC-6” RGB LEDs.

We’ll see how well my fly-by-night land pattern artestry holds up to the real challenge of actually putting the thing together. Fortunately the ATmega 168/328 microcontroller will be a DIP300 package held in a standard socket with legs bent out and surface soldered- I decided a socketed mcu would probably be a good thing given that I didn’t add an ICSP header, only a FTDI style TTL serial header (SIL header fit between the rows of LEDs). Everything else is in a .025 pitch TSSOP package. We’ll see how it goes. I’m going for “learning experience” with this one. If it works that’ll be the icing on the cake.

And yes, I’m calling it the “Twinkle Tag”.

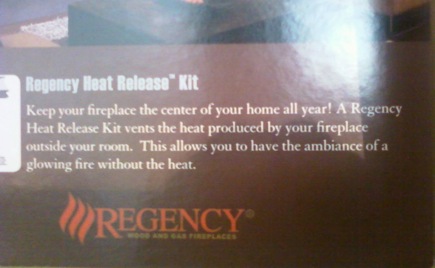

The Moron Fireplace

First Man had Fire.

Fire would be found in a pit or later a fireplace. With fire came soot and smoke.

Eventually Man put his fireplace behind a pane of glass, eliminating smoke in his dwelling.

And again Man figured out that he could have a fireplace burning gas that did away with smoke and the necessity of building and tending a fire.

Today Man has built a fireplace (The Moron Fireplace) which burns gas with fake logs for the singular purpose of decoration, not heat. Indeed this fireplace (THE MORON FIREPLACE) expels the heat generated by the flickering gas flame OUTSIDE the building. On purpose.

This is excess in living. This is how we know we’re better than those who can’t afford to heat their homes.

REFUEL 2010 at Laguna Seca Pt. 2- Everyone Else

Since I already posted about my experience at Refuel 2010 now it’s time to look at who all else was there.

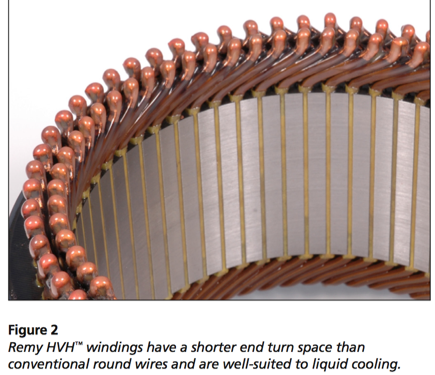

I was excited to see Palatov Motorsport’s cars. I visited the Palatov shop last July in Portland but at the time the dp1 was out of the shop and the dp4 hadn’t been built yet. They brought the dp1e electric racer and the dp4 hayabusa-powered mini-racer. The dp1 is powered by a Remy PMAC motor and impressively compact Rinehart Motion Systems inverter, coupled with a healthy Thunder Sky battery pack. While solidly in the prototype phase, the car is coming along quite impressively and makes quite an impression in person. From looking around the Remy website I suspect the motor they’re using is from Remy’s “off the shelf” series of motors designed for hybrid drive systems. It uses an interesting construction technique they call “HVH- High Voltage Hairpin”. Basically, the windings are made of rectangular wire slotted very neatly into the stator laminations, for measurable improvements in power density and efficiency. It’s really a very sexy looking motor.

(Taken from the white paper available at http://www.remyinc.com/hybrid.asp)

(Taken from the white paper available at http://www.remyinc.com/hybrid.asp)

Palatov says he’s planning on selling a EV drive system based on the Remy motor and RMS inverter. It’ll be very interesting to see what the price point for that sort of a system will be.

The dp1e looked great on the track, they took a close third in the time trial after the Kleenspeed WX10 racecar and the Wrightspeed X1. Given that both of those are AC-150 powered, with approximately double the peak power of the dp1e it’s not a surprise, but impressive how close it came.

See the rest: Read the rest of this post »

REFUEL 2010 at Laguna Seca Pt. 1- Me

Now in its second year, the REFUEL all-electric expo and race at Laguna Seca Raceway was held last Sunday, the 11th of July. Held by Speed Ventures, it’s an opportunity for owners of electric cars or motorcycles to drive on track in a track-day setting, as well as compete in a time trial style race against the other electrics. I missed the event last year but made a point to attend this time, and to my great satisfaction was able to bring the electric MX5.

It was a bit of a stretch to get the car down to Monterey, arranging trailer and towing facilities around my friends’ schedules, but in the end things worked out well- the car made it down and back safely with no incident. There was even enough space to bring the electric bike and electric recliner- both of which fulfilled their purposes very well and were great fun to have along.

We arrived at about 8:30 AM after about three hours on the road and found the racetrack hidden in thick fog. By the time the first session came around the fog had burned off though, leaving beautiful sunny, breezy weather for the rest of the day. I made it out for two sessions on the track, for exactly two laps each before the batteries were too soft to continue. Coming over the big hill to the corkscrew corner on the second lap was accomplished at near a crawl.

I had a good chance to get more of a feel for how the new Rudman regs perform, mainly how much additional convection cooling they need in operation- I had to keep chasing the overheating reg around the pack with an electric fan. It’s definitely good to be putting some cycles on this pack, it’s clearly starting to work itself out and become more balanced. The battery I thought was weak and having self discharge problems seems to be behaving better. I am wondering if perhaps my old balancer system was causing a higher quiescent discharge on it than on the others.

My car was the only one driving on track with lead batteries, and one of only two brushed DC powered cars- it’s not a surprise that it was the slowest car out there. Despite that it was incredibly fun and gratifying to take around the track- and what a beautiful track. Sure I could have done better racing in practically anything gas-powered, but that’s not the point. Finally after three years working on the car I can drive it and charge it at a racetrack 120 miles from home- that’s really something. The car is unique- smooth, quiet and really pleasant to drive, even reasonably fast when fresh off the charger. Two laps, about four and a half miles of hard driving is pretty much the limit before the voltage sag completely destroys the driveability of the car. According to the Cycle Analyst that’s about 12-16 AH in- I’m not sure if this is a reasonable useful capacity out of the 55AH Optimas or if they have suffered in the last year they’ve been sitting full but rarely cycled.

The bike performed excellently as usual as a speedy runaround, and was passed around a bit for test rides. The electric recliner was the real star of the show. Sitting out of view in the truck while remote-crusing it around the paddock was stupid fun. We maneuvered it over near the Palatov Motorsports trailer and distracted them from their cars for a bit with some antics that Dennis ended up mentioning on his site (See dp1e section, 7/9/10 post). Then at the end of the day I traded a ride in the chair for a ride in a Tesla Roadster- something I had never managed to get before. Suffice it to say the Tesla knocked my socks off.

All in all, a fantastically successful day.

See part Two for my thoughts about the other cars that showed up to the event.

Back in DC/DC again

Despite the troubles I was having before, the DC/DC converter has mended itself and appears to be working entirely as it should. It looks like the problem was caused by enabling the converter with the ignition signal before the precharge was done. The idea being that the precharge circuit is usually used in situations where the converter is disconnected from the pack when the ignition is off, so that it soft-starts itself and starts running on its own when it is energized. The enable input apparently overrides the soft-start procedure. When used with the enable input the converter is supposed to be connected to the pack all the time. The converter is usually not meant to be run using both like I am. So, if I switch on the pack and then switch on the ignition too soon it will close the main relay inside under the cap charging load, which probably caused the relay contacts to lightly weld shut. I spoke to Belktronics about the problem, they recommended testing the precharge circuit by attaching the converter to the pack through a 110v lightbulb- the first time I did it I got a big flash as the caps charged. At some point after then the fused contacts seem to have un-fused and the precharge circuit works OK again. I just have to make sure to always leave it adequate time to precharge before enabling it.

Back in Action

After having the last couple weeks of my life stolen by first illness, then jury duty, I’m finally back in control and ready to get the stuff that needs to get done done to make the projects that need to happen happen- like the car and the kart. I didn’t shave until I was booted from the jury selection- It’s probably just superstition but hey, it can’t hurt to cultivate a “you don’t want me on your jury” look. What a relief to get out- the trial presentation for those selected will likely stretch into August. A real messy attempted murder case.

So, what’s up now? I’m making plans to get the electric MX-5 down to Monterey on Sunday for the Refuel expo/trackday/event at Laguna Seca. I’ve installed a set of MK3 Rudman Regulators to replace my home-built balancer setup as I discussed before. I’ve given the car a couple of test cycles to try to figure out what is really working and what’s not- the new regs look promising but need to be dialed in. There appears to be one really weak battery that is limiting the performance of the whole pack. And the brand new Belktronix DC/DC has something going on that I need to figure out. It’s blown a couple of HV fuses now (where do I recognize this scenario from?) If I can’t get it working it won’t ruin the weekend however, the aux. 12v battery seems to be up to the task of running the car. I got about 15 miles of driving today with heavy vacuum pump and headlight use before the aux battery ran hit the Zilla’s cutout point, and it wasn’t fully charged when I started.

It’s the little things that stack up and become seriously frustrating. The cycle analyst reports wildly varying and totally wrong current readings while charging the car, while seeming about correct under discharge. Even my Fluke 337 current clamp meter is acting sketchy and not entirely trustworthy, particularly for voltage or resistance measurements. There’s definitely something wrong with it.

So, like usual with the practice of trying to get stuff to work there is the sweet and the sour- some things go right the first time, more often things need more attention. Patience and perseverance.

I’m really looking forward to the event on Sunday, I know some people I want to see will be there and I expect plenty of people I will enjoy seeing but haven’t thought of will show up as well. Hopefully the Miata performs OK. Looks like my friends and I will also have the electric recliner in tow. After reworking the battery box today it is even more solid, and stealthy than before. Good stuff. Sadly we didn’t get a chance to set up the remote-controlled auto-recline feature. Another day.

In: Battery Regulator, EV Miata, Life and Times

How Much Electric Kart Can You Build in a Day?

Last week I rebuilt the kart with fresh fasteners and axle bearings, plus picked up a steering wheel and some #35 sprockets. Then, once the Mars motor looked repaired and good to go onto the kart I picked up a handful of 7/8 keyed #35 sprockets from Surplus Center. The parts were forecast to arrive on Thursday- so I made plans with my friends to bring everything to Laney and try to get the kart running. I came in at two and got started- about eleven hours later the kart was driving, a half an hour later it was broken, and finally at about four in the morning we all went home.

Miles drew up the motor mount plate in CAD and cut it out of 3/16 mild on the CNC plasma table. It’s bolted right to the outer bearing frame support with slotted holes to adjust the chain tension- the stick he’s using is to help support the motor while he tightens the plate in.

Micah made up all the cables out of 6GA welding cable. We didn’t find enough lugs locally at any sort of reasonable price so we made “lugs from the ghett-o” by smashing copper tube around the wire, filling with solder then drilling. A little trick I learned from Home Power Magazine about ten years ago. I mounted the Sevcon Millipak controller, contactor and fuse, and made up the control panel, throttle, and hall sensor wiring harnesses.

See the rest– Read the rest of this post »