Solar Power is GO

It was dissappointing to confirm that my Prosine inverter was toasted– so I hadn’t gotten around to working on the system for a while. Today I remembered that I have an old modified sine wave inverter in storage from the first and never functional version of the solar power system- I dug it out and hooked it up:

I realize it’s just a bit over-wired, 2/0 for a 300 watt inverter is truly ridicculous- but it’s not hurting anything and the value of just being able to hook parts up without redoing a million different things is truly wonderful every (infrequent) time it works out that way.

I realize it’s just a bit over-wired, 2/0 for a 300 watt inverter is truly ridicculous- but it’s not hurting anything and the value of just being able to hook parts up without redoing a million different things is truly wonderful every (infrequent) time it works out that way.

I ran my macbook charger on the inverter all afternoon, works great! I’m going to let the solar float charge the batteries again tomorrow and then I will be set to hook up the PFC charger to tune its voltage cutoff, now that I have a good way to pull power out of the batteries. (this is all part of the plan to characterize the behavior of the PFC’s regbus, as described previously) I still plan on hacking up a 12v laptop charger and installing some 12v lights but that can wait, it sure is cool to be able to use the solar power I haven’t been taking advantage over the last several years.

Simulating Spin-Out Skid Marks

Sometimes you’ve got to write a script- like to generate a wreath out of cams… but for some things you’ve just got to bust out the magic markers and rubber bands-

Gave me just the information I needed-

Creative Radial Clones: SVG with Inkscape and PHP

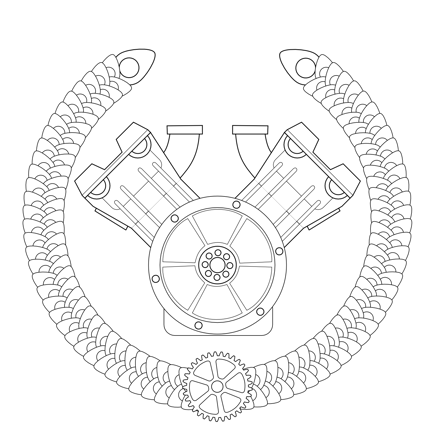

Lately I’ve been working on drawing up some graphic desgin ideas I’ve had, mostly centering around the race team “Project Fate”… thinking along the lines of logos to try to figure out a team identity, aesthetic- imagery of engines, oil stuff, with a sort of old fashioned simple powerful monochrome theme. I’ve been working in inkscape because Illustrator is expensive and I kind of dig the simplicity of Inkscape.

To cut to the chase, I thought it would be cool to make a “wreath” out of shapes resembling cams from an engine, so that it would look a bit like a crest formed from wheat sheaves. It’s trivial to draw a simple cam shape by just elongating a circle- the proportions of the cam lobe are easy to tweak. The real challenge is arranging them in the circle with the proper alternating radial and angular offset to make it really work. Maybe it’s possible to do this using the Inkscape clone array dialog- but I wasn’t able to figure it out- so I did a little research on SVG and decided to use a PHP script (which I’m pretty familiar working with) to generate a SVG document with all the clones mathematically generated.

A couple of tips on using PHP to generate SVG- it’s super easy, but there are a couple of tricks that got me caught up for a bit:

- You must place this line header(“Content-Type: image/svg+xml”); before PHP outputs any text

- You must use echo ‘<?xml version=”1.0″ standalone=”no”?>’; to print the XML tag, PHP doesn’t particularly like the <? … tag opening unless it’s within quotes

- Remember that when you are echoing SVG tags that use double quotes to surround them in single quotes, and vice versa.

Simply placing an inkscape SVG file contents within a PHP document with the header() line installed won’t work, you’ve got to attend to that <? … > tag- past that you should be OK.

So. I created the cam shape just how I wanted it, placed the center around which I want it to be rotated at (0,0) and oriented straight upwards- then copied that SVG group into my PHP file, then created a loop to generate the clones. I plan to make the PHP file a bit more interactive using a form later on, but this did indeed get the job done, with style. It is very empowering to have complete mathematical control over whatever happens- the true power of scripting. The script is also extremely versitile and easy to tweak, and with in-browser SVG rendering, it’s pretty fun to work with.

Without further ado-

View the PHP generated SVG as seen above

View a generalized version of the PHP source code, usable for any purpose

Once you’ve used the PHP to get the design you want, you can import that back into inkscape and add other design elements to it or tweak the parent object to tweak all the clones- neato!

I drew up a timing-gear and a somewhat abstracted 90Ëš V-engine to make this- it’s a rough draft, but I like where it’s going:

I realize this is not the most exciting use of PHP generated SVG ever, but it is pretty neat to be able to apply the power of scripting to vector graphic design. I hope this little experiment will be useful to someone!

Wiring Up

I spent a good many hours today working on the car- got a lot done, and boy is it plenty hard work.

I basically just ran the necesesary power cables front/back under the car.

You can kind of see there, the welding cable is run in orange “Smurf Tube” from the home depot. It is fairly tough flexible plastic corrugated tubing. The tube is attached to the powerplant frame with huge zip ties, two tubes for the 2/0 power cables, one for the 8 GA wires that will attach the charger to the high voltage. I made and attached the motor leads in preparation for installing the front rack.

You can kind of see there, the welding cable is run in orange “Smurf Tube” from the home depot. It is fairly tough flexible plastic corrugated tubing. The tube is attached to the powerplant frame with huge zip ties, two tubes for the 2/0 power cables, one for the 8 GA wires that will attach the charger to the high voltage. I made and attached the motor leads in preparation for installing the front rack.

I’ve started to deal with the task of attaching all the lugs and terminals to the welding cable- it was fun for the first couple tries. I am using heavy duty lugs from EVSource and the diamond crimpers also from EVSource. The lugs are good, I’m a little unhappy with the crimpers- I have the dies set to 2/0, but it seems to be over-crimping somewhat. The lug metal is kind of extruded out in a little tab, and of course making the crimp requires a borderline ridiculous amount of effort, it’s impossible to make the crimp without bracing one handle of the crimper against something. If I were doing it again I might shop for a hex crimper instead of a diamond one. The crimps do seem to be “working” though, the connections are very solid.

I’ve started to deal with the task of attaching all the lugs and terminals to the welding cable- it was fun for the first couple tries. I am using heavy duty lugs from EVSource and the diamond crimpers also from EVSource. The lugs are good, I’m a little unhappy with the crimpers- I have the dies set to 2/0, but it seems to be over-crimping somewhat. The lug metal is kind of extruded out in a little tab, and of course making the crimp requires a borderline ridiculous amount of effort, it’s impossible to make the crimp without bracing one handle of the crimper against something. If I were doing it again I might shop for a hex crimper instead of a diamond one. The crimps do seem to be “working” though, the connections are very solid.

There’s still a whole lot of integration that has to happen here. It’s doubly difficult because I am largely improvising my way along. I’m hoping to hook up the batteries and give the motor/controller a real first test this weekend. There will be video.

LeMons Arse-Freeze: Year Two

This year’s Arse Freeze-A-Palooza is still many months off, it’s true. But in the members of Project Fate’s collective busyness and brokeness, we decided it would be wise to shoot for one LeMons race a year for now- so Arse-Freeze ’09 is the goal. Last year we scrambled to get our racecar ready for Arse-Freeze ’08, with the rollcage, brakes and mad zip-tie work, this year we know where we stand a bit better and want to prepare in advance. So, where are we?

Last year’s racecar, the “Fatemobile Z” ’86 300zx is in Jonathan’s garage in Davis. After finishing the race last year, we trucked it home, dropped it off and left it for a couple months. When we fired it up the again in January or February it became quickly clear that there was no oil getting into the head- along with deathly sounding ticks coming from the top of the engine, you could see through the filler that there was no oil inside. We replaced the oil with a “suicide mix” of synthetic blend, ATF, seafoam, and magic engine oil treatment that was in the clearance bin- to no avail. We did not replace the filter, though.

Fast forward another month or two- yesterday Jonathan and I spent some more time trying to get the ol’ girl flowing. Right off the bat, we replaced the filter and put one of our spare wheels on so that we could take the passenger side of the car off jack stands… just trying to eliminate possible points of failure. Running the engine gave clear indications of different behavior, the oil pressure gauge made it up to the “30” line, although was not responsive to revving, and oil was observed through the filler, seemingly flowing well. We popped the non-filler side valve cover off to check that things looked wet under there too… and they did. It’s nice to know that the valves are getting oil- unfortunately the engine still sounds like crap. It clatters and ticks, and runs really unevenly- sporadically the RPMs at idle will bog, or if you hold the throttle partly open and hold the engine at a constant RPM it will hold for a little while then seem to bog again and sound really terrible. I’m not experienced enough with diagnosing engine trouble to say for sure, but it could very well be misfiring.

And by the way- it’s a good thing we didn’t have a flat during the race- we never really tested our spare wheels… the tires rub against the struts, and with the spacers we bought the lug nuts aren’t long enough to really trust… in my quick assesment. The spare wheels are 16’s from a Infiniti Q45. Nice wheels, different offset. We had no idea how rare 16″ 300ZX wheels were until we found a set, bought them, bought tires for them then tried to find two more.

Jonathan and I checked the spark plugs next, one was significantly loose, one had something funny going on with the threads but more interestingly, one showed no evidence of “burn”- that sort of coating of matte gray soot. The plug wire is well attached on both ends and it definitely has fired in the past, the engine used to run nice and smooth- so— ignition? fuel? compression?

We didn’t get to test for all those things. There are definitely some shady things about that car and it’s wiring, I hope we can get a clear answer next time we work on it.

And what if we find no compression? When I talked to them a bit ago Jay and Nick strongly suggested that we stick with the Nissan- we know what handling problems we need to address with it, it’s generally been quite reliable, and it has the potential to make a really quite good racecar. Plus, building that rollcage really was stressful and an amazing pain in the ass- heavy tough DOM steel + hydraulic bender + notcher + TIG welder operator at work all day and no way to tack weld in her absence + frozen fingers + rain… even 6 months later we can’t forget how big a drag that was. So, a junkyard engine, and an engine swap? Oh gawd do I not want to go there!

For now, let’s go with the other possibility- the engine will fix itself, or just require minor work. Then, we just give the car a nice new paint job, install the $50 Eibach springs Christian found on craigslist, fix the CV joints, replace the fuel hoses, and put together all the lights and sound effects and body mods we never even got a chance to consider last year. Plus, we’ve got a trailer that is pretty close to ready to tow a car on, so we can take it to the autocross over the summer and get an idea of how to drive it cleanly… and faster for the next race. Or, of course, work tirelessly on the engine swap for that shitty car in the Davis 110 degree summer heat. Right.

It may not seem it… but you’ve just got to believe it’s worth it.

And maybe a perfect different new racecar will just appear for us, something that it’s worth starting from scratch… I think I’m going to go up and spectate the Reno race May 23, 24- My dad wants to see what these LeMons races look like.

I wanna ShopBot

The ShopBot CNC router hasn’t always been an object of desire for me- It’s easy to judge it as inferior because it doesn’t use linear rail bearings, ballscrews or servo motors in favor of ball bearings on rails, rack and pinion gears and gearhead steppers. I have learned more of the capabilities and strengths of the ShopBot by seeing the work BecauseWeCan do with theirs, as well as hearing Jeffrey talk about it at EatFoodTalkShop. Last thursday he described the some features of the machine in a way that really piqued my interest- mainly concerning the “Job Code” that is used by the ShopBot’s control software. As well as mentioning that they were planning to open and document the language they created and use (as opposed to Gcode)- which it appears they have now done, he said it is a much more comprehensive script-capable language than Gcode, with lots of built-in functionality- including built-in randomization.

That in particular really got me thinking- After quickly reviewing the documentation, it appears that the ShopBot code- “OpenSBP” supports user vairables, some math (although it is not described in the manual), basic flow control, BASIC style subroutines, windows message box triggering, file I/O. It’s a pretty good start- I can imagine some reasonably interesting possibilities of dynamic part definitions from within the SBP files. I am really attracted to the idea of being able to define parts based on random variables, such that every part will be “designed” on the spot, randomly. It is of course possible to write a seperate script to generate some Gcode or “dumb” SBP code, but the idea of having the randomness executed at machining time is sort of the ultimate in instilling organic ephemerality to the machining process.

It’s clear that the SBP standard is still under construction, as is its documentation. I believe that it looks better than Gcode, and has a lot of potential in future revisions. That said, the documentation is a bit vague on key issues at the moment, and there are still some complex processes that aren’t going to be efficiently implemented in SBP. You can’t define even simple data structures in SBP and I personally am much more familiar and happy with with C-style programming over BASIC style programming. Although it is not described in the current programming manual, I presume there is a random number function- this could easily be used to vary the parameters of some texture defined in SBP, like by varying the Z axis plunge depth at each point in the texture. I have thought of an application where I would like a randomly generated pattern of overlapping concentric circles- for a more logically complex operation like that I would want to work with an environment that would let me have data structures- arrays at least, and very well implemented subroutines, looping and flow control. A script to generate complex random toolpaths could be written in C, or Processing, or PHP, or whatever- but that abstracts it from the actual execution of the job, which as I mentioned earlier, is one of the coolest parts about scriptable job code. At least it is clear that the ShopBot control software is command-line accessable- that helps. Maybe there could be some way to include hooks to other scripting software from within a SBP file…

Anyways, I like the direction the ShopBot folks are headed with SBP. It’s already better than Gcode, and is only going to get better by documentation and standardization. I can imagine that I would enjoy very much working with a ShopBot machine and using the SBP- it looks like lots of fun. I was thinking before about wanting to build a CNC router- but now I find myself qute attracted to the ShopBot package- I don’t doubt the machine’s quality or capability to do what it’s designed to do, and their software/hardware package integration and support is very attractive. I feel like I could actually get somewhere right out of the box with the ShopBot system.

So why exactly do Iwanna one now? Because my mind has, as is inevetable, begun to imagine what I could do with it. Just like Jeffrey and Jillian at BecauseWeCan did, I am definitely dreaming about what my ShopBot business plan would be. I can think of about a half a dozen different relatively simple things to start with that I could design and be able to manufacture with something like a ShopBot. I am excited about that quickness from design to prototype through to manufacture- just like it has for BecauseWeCan, it’s a straight-fire way for someone with a interest in visual or functional design to turn cheap materials into complex prototypes that would be very nearly impossible to make any other way- and then redesign or manufacture those designs with just as little trouble. Seriously it is amazing the variety of unique furniture and interior pieces BecauseWeCan make with the CNC, good bits, good wood suppliers, sanders and a good finish spray setup. The emphasis is able to be focussed much more on design rather than the mechanics of manufacture.

So, maybe within an few years I’ll borrow some money, crank out some designs and nab a ShopBot- I think it may be the fastest route to some of my biggest goals.

A Million Loose Ends

Along with continuing to work on assembling the battery monitor modules (Update soon—) I spent some time today taking care of a few issues that needed to be addressed on the Miata. First I replaced the tangle of inline ATC fuse holders as seen above with a much tidier marine/RV ATC fuse block I purchased from EV Source. It is much less of a hack job, and I noticed the branch circuits were seeming to operate with less effects of voltage sag after I got rid of that unholy mess of butt crimps. Now it looks like this:

Along with continuing to work on assembling the battery monitor modules (Update soon—) I spent some time today taking care of a few issues that needed to be addressed on the Miata. First I replaced the tangle of inline ATC fuse holders as seen above with a much tidier marine/RV ATC fuse block I purchased from EV Source. It is much less of a hack job, and I noticed the branch circuits were seeming to operate with less effects of voltage sag after I got rid of that unholy mess of butt crimps. Now it looks like this:

Heh, in case you were wondering, VAC is the power brake vacuum pump, BLO is for the marine bilge blowers I installed in place of the heat/vent/AC system, POP is for the electric trunk popper I installed, H2OPMP is for the Zilla watercooling pump. I added a wire for it later on. The blue supply wire originally powered the heater blower and is attached to a 35 amp resettable breaker in the fuse box on the driver’s side. This fuse block is only energized when the keyswitch is in the “ignition” position.

Heh, in case you were wondering, VAC is the power brake vacuum pump, BLO is for the marine bilge blowers I installed in place of the heat/vent/AC system, POP is for the electric trunk popper I installed, H2OPMP is for the Zilla watercooling pump. I added a wire for it later on. The blue supply wire originally powered the heater blower and is attached to a 35 amp resettable breaker in the fuse box on the driver’s side. This fuse block is only energized when the keyswitch is in the “ignition” position.

I was in such a hurry to get the interior of the car back together after having it apart for so long when I was working on the mid-position battery rack that I neglected to run wires for the various things that would need to be wired front/back. I had been dreading it, but it actually didn’t end up being too bad to run the data cable for the rear PakTrakr remote and two Cat 5 cables out from under the parcel shelf through the “fuel tank bulkhead”, under the center console and out through the firewall. I’ll need one Cat 5 line for the BattRegs, and I included an extra- I can imagine reasons I might like to have some more wires front/back- and would rather not have to run more. Like if I get around to installing a fuel-filler-open interlock circuit.

Blue = Cat 5, Gray = PakTrakr, Red = Power for vac. pump and trunk popper.

Blue = Cat 5, Gray = PakTrakr, Red = Power for vac. pump and trunk popper.

Finally, I think it’s worth noting something I came up with recently- It seemed like a good idea to sheild the lug terminals on the motor for safety- but I don’t have any well-fitting rubber boots for those lugs- I had seen photos of someone’s EV project where they had slathered every electrical connection on it with thick silicone caulk- I caught wind of this DAP ‘temporary’ caulk- called “Seal and Peel”, meant to be used for weatherstripping. I bought a tube at my local hardware store and applied it to the motor terminals.

As you can see, it’s crystal clear, and was pretty easy to work with and sculpt around the terminal. It does not adhere strongly (by design) and while I haven’t tried removing it from these terminals, I’m sure it will be easier than traditional silicone sealant would be. And, it’s vanilla scented!

As you can see, it’s crystal clear, and was pretty easy to work with and sculpt around the terminal. It does not adhere strongly (by design) and while I haven’t tried removing it from these terminals, I’m sure it will be easier than traditional silicone sealant would be. And, it’s vanilla scented!

1/2 Ton of Batteries

… very nearly, that is.

First, I picked up a pair of L16s to wire into the little photovoltaic system I set up years ago- and never bought proper batteries for. I had an inverter on the system (prosine 1000), but it seems to have broken at some point- I don’t know when or how, and I was informed that the prosine inverters are non-repairable. The charging circuit and charge controller are working just fine- the batteries are sitting there float charging. Unfortunately I have no way to use that power at the moment, I need to get some 12v CFLs and hack up a 12v powered MacBook charger, and maybe pick up a new inverter.

First, I picked up a pair of L16s to wire into the little photovoltaic system I set up years ago- and never bought proper batteries for. I had an inverter on the system (prosine 1000), but it seems to have broken at some point- I don’t know when or how, and I was informed that the prosine inverters are non-repairable. The charging circuit and charge controller are working just fine- the batteries are sitting there float charging. Unfortunately I have no way to use that power at the moment, I need to get some 12v CFLs and hack up a 12v powered MacBook charger, and maybe pick up a new inverter.

Second, and also purchased through Jim Ramos at American Battery in Hayward, 12 brand new, matched Optima Yellow Tops (D34) for the car! Wow, that’s a bunch of batteries! Things are looking good, so far they fit just fine in all my racks and boxes! I figure I should be able to test drive the car within a few good days of work- tieing up all the loose ends with the charging system and various plexiglass sheilds I plan to install over things will take a bit longer.

Second, and also purchased through Jim Ramos at American Battery in Hayward, 12 brand new, matched Optima Yellow Tops (D34) for the car! Wow, that’s a bunch of batteries! Things are looking good, so far they fit just fine in all my racks and boxes! I figure I should be able to test drive the car within a few good days of work- tieing up all the loose ends with the charging system and various plexiglass sheilds I plan to install over things will take a bit longer.

In: EV Miata, Renewable Energy System

The Military- Personal effectiveness and discipline

Last Monday (3/23/09), on the last day of my Dad’s and my weekend trip to Colorado we visited the US Air Force Academy in Colorado Springs. It was somewhat on impulse, it had not been part of the trip itinerary, as far as I was concerned. I did not have expectations for or preconceived thoughts about the visit, I ended up finding it extremely worthwhile. In addition to the stunning natural surroundings, the shock of the crisp air and sprinkling of snow (!!), the presentation of the campus through the visitor center and (inspirational/propaganda/recruiting) video shown there, as well as through the appearance and atmosphere of the campus and centerpiece chapel led to a stimulating, thought provoking and somewhat reaffirming experience for me. The reverie induced by the Grand Marquis may have also had play in my perception.

To be fair and honest, I know very little in the way of substantial fact about the military, its organization or the strengths and weaknesses of the AFA in particular, or the student body of the AFA. All my views and opinions are shaped from my perceptions and what I’ve picked up from people I know and the news and media that I pay attention to.

The AFA is centered around an ideal, with a long history of the process used to achieve that ideal. The “Honor Code”- white glove inspections of students’ rooms- prohibition of keeping “civilian” items in the dorm rooms until after Christmas of the first year in school- uniform- practice with doing that sort of synchronized gun-slinging often seen as part of the public image of the Air Force… The video in the visitors center stated that all students must personally, truly believe in the cause and worth of the process and the institution. Everyone has to work hard, everyone must be able to trust their compatriots, and trust that their compatriots are working hard too.

The AFA is an excellent engineering school, as I understand. Many people are educated there then go on to serve for a few years and eventually end up working in engineering. I would not be surprised if ex-Air Force engineers make excellent “civilian” engineers, I would not be surprised if they exhibit, as a whole, better discipline, better attitude, better communication and trustworthiness than other engineers as a whole.

From this perspective, the military in general and the AFA would seem truly excellent- they would seem to be the place where the young men and women of optimal talent and character would go to work with other similar young people. The military would be a cache of the best of the best.

What’s the rub? I do not believe the military attracts the whole best of the best. I think a huge section of the young population of the US is entirely disinterested, even disenfranchised by the military today. Why?

- Politics- The military is, in just about every way, pretty far right. Fundamentalists don’t get along well with anyone outside their circle, especially opposite fundamentalists. I think there are plenty of borderline right-fundamentalists associated with the military, and I think there are plenty of brilliant hard workers who lean left.

- Image- Bureaucracy. “The War on Terror”. Iraq. Cheney. Blackwater. Halliburton.

- Faith- The trademark of the AFA is their chapel. It’s an imposing, spare and beautiful building, representing Protestants, Catholics, Jews and Buddhists, listed in order of space allocation. I think that the atheist presence in the world is more prominent and growing faster now than ever- I think people of different religions are getting better at respecting one another’s religions- I feel like there is more friction between faith and non faith than between different faiths. I know I feel significantly more comfortable when faith is left entirely out of the equation.

- Machismo- Just watch some recent TV ads for any branch of the military. That image is not for everyone. People who could be very valuable to the military, especially these days with the internet and computers being so important might be seriously turned off by that macho.

- Technological Backwardness- I know, it would seem trivial and shallow, but the Air Force PR tagline these days is “Air – Space – Cyberspace”. Really, guys? Cyberspace? It’s like putting up a huge billboard to everyone who’s basically up-to-date with computers or the internet saying “I’M STUCK IN THE EARLY 90’s”. The AFA visitor center had blurbs about how all the dorm rooms had “microcomputers” on a “information network”- really, do they understand how IMPORTANT this is!? Computers and the internet are incredibly powerful, the more people they attract who have a sincere aptitude with computers, the better it will be for them. Stuff like “Cyberspace” or “Microcomputers” will put up red flags and repel just those kinds of people! edit: I’ve been a little more perceptive about it since writing this piece- it seems that the term “cyber” in all it’s various contexts is pretty heavily used throughout the media and even academia- so maybe it’s a bit more legit than I make it out to be. I still think it sounds dumb. So there.

I don’t think this is new, and I’m sure I’m not the first one to think of arguments like this. I do think it’s disappointing. In some ways, I think the invasive, life controlling sort of regimen present in the military, or in the military academy is something that I would welcome and would imagine would have a positive effect on my life. Sometimes I feel frustrated by my lack of discipline- I hate to realize that I have wasted time listening to crap music, or watching TV shows, when there is more rewarding stuff to be done- I would welcome a system in which I am being held accountable for all my behavior, and everyone else is too. I would truly appreciate being in a community in which people are honorable and don’t try to cheat and get off as easy as possible for the sake of indulging their lazyness or privelege. At UC Davis there are tons of people who do not subscribe to the academic honor ideal- you can just hear it in the way people talk about classes and teachers, plenty of students are shallow and lazy- worried about getting good enough grades and maintaining rolicking social lives. Some people find drive within themselves to work extremely hard academicaly- but for each truly honorable student there’s someone who is only in school for the sake of satisfying their parents and feeding their social life. There is no student body cohesion. That is not to say that there aren’t thousands of people who get world-class educations from institutions like UC Davis, and that’s not to say that the school environment is bad, or doesn’t work for everyone. There are groups on campus that are tightly knit, hardworking, co-trusting, and where you will find members being accountable to each other and taking care of each other. Unless you find that group, you don’t get that comraderie. At the AFA there is a comraderie specifically built out of just being there- at least they way they talk about it, the “Honor Code” and general attitude serves to make everyone part of the group- right out of the box. Unless you are very brilliant, or very lucky, you will probably not find a substance-based group like I’ve been describing at Davis for the first two, or even four years. I realize that plenty of people have social groups that may fill a similar need for them, but I personally don’t find purely social engagements a fraction as energizing or satisfying as actually getting something done- working with others toward a goal, and making it happen.

Since I derive my personal satisfaction so highly from “getting stuff done”, and I was feeling hopelessly ineffective in classes at Davis, I decided to take time out of school- for now, indefinitely. I don’t know where I am going , or via what path. I do feel encouraged, though, to feel like I have this little bit of insight into these institutions and how they do or don’t work, for me and for others. It makes me feel better about my decision to follow my interests, to try to create for myself the sort of honor/trust/effectiveness/hard-work/team-work situation that I know exists. I want to work with others, to work as hard as I can on the facets of a project that I can be most effective with, and trust that they are giving the facets they are responsible for the same sort of attention. I realize that these situations arise most readily in school (grad school?) or on the job (in a really good job)- but I’m willing to give it a shot. I have derived great satisfaction from the contacts I have made and the work I have invested and the stuff I have learned over the battery regulator project- although I hope for some team-work opportunities in the future.

The keys here are knowing other idealistic people who aren’t employed, having some kind of idea that everyone’s into, and of course having the facilities and capital to make it happen. We’ll see. A guy can dream, right?

Battery Regulator- the OTHER part of the project

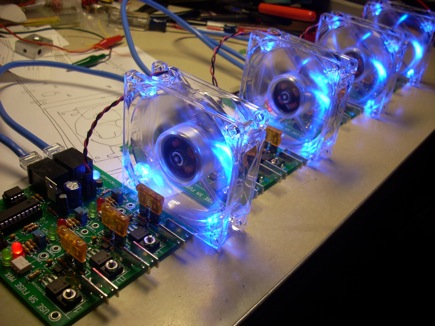

I devised a workable fix for the circuit FAIL previously described and finished assembling a set of four battery regulator boards- their relatively small size belies that they have a LOT of parts on them! They are a pretty involved assembly project!

I haven’t tested everything about every board, but as far as I can tell, so far everything seems to be working as it should.

What’s Next?

Let’s review the theory of operation of shunt regulators- The charger fast charges (constant voltage) the series string of batteries until a regulator detects that a single battery has reached a voltage setpoint, indicating that it is full. The regulator starts shunting the charging current off that battery. The charger then throttles down to an “absorbtion” rate charge (constant current), and as other batteries fill, their regulators shunt off them too, until every battery has reached the voltage setpoint as detected by the regulators. At that point, the charger enters a float charging mode until it is unplugged from “land” power.

I now have regulators that detect voltage, are able to shunt current and communicate with a master via one serial port of currently undefined protocol and two digital lines that can be pulled low or high by the µC pins. I need a way to instruct the charger to enter the second and third stages of charging. The charger (Manzinita Micro PFC20) has a 6 connector RJ12 port called REGBUS which is designed to allow the charger to work in sync with Manzinita Micro’s Rudman Regs. It’a an analog interface, electrically specified pretty well via the files on this page. There is no specific information or How-To on faking the interface with a microcontroller though- it’s a simple bus though, so I decided to figure it out myself. I have a current clamp meter to monitor the charger’s output, and some potentiometers and RJ12 plugs and wires to generate signals on the REGBUS, I’ll see what happens. I was thinking of picking up a pair of L16 batteries to test with, which I can then integrate into my long neglected solar-electric power system.

I can envision this working one of two ways. Either the charger current response is proportional to the analog signals on the REGBUS, or the current response is preset and the analog signals are used as triggers to move the charger into different preset modes. I hope it’s the latter, so that I can generate the analog signals with a few resistor networks and optocouplers- if it’s the former, I might have to look into digipots or DACs.

No use thinking too much about it before actually doing the testing and figuring out what I’ve actually got to work with here.

In order to make the charging system work without intervention, I need this master to monitor the “Reduce” and “Finish” digital signal lines on my “BatBuss” connector and generate the analog voltages needed by the PFC charger. In future versions, I’d also like to integrate…

- CAN Bus for reporting state and voltages, AH counts and SOC

- battery current sensor, charging current sensor

- Solid state relay switching of AC side of charger for protection or automatic time of day charger on/off switching

- one RGB LED PWM channel for making a Tesla-style “fuel filler light ring”

- data logging

Sounds good, right? For now, I just want to get the batteries charging. Speaking of batteries, mine are on order! Should be arriving Apr. 8!