Zilla Coolant Redux

As I noted a while back, while I was pleased with the general concept and execution of the Nalgene water bottle as coolant reservoir, it had sprung a significant leak shortly after installation. Soon therafter the leaking increased heavily, draining approximately 1L of coolant in just a few hours. After inspection it quickly became clear that the bottle itself was destroyed- the mechanical forces on it from the bung in the bottom and the clamping forces from the mounting clamps were too much for the tough but brittle polycarbonate bottle.

I decided to redo a similar setup, but change a few elements based on this experience…

I picked up a new bottle, one of the soft, more flexible white plastic style ones. I mounted it with a foam tape layer under the mounting clamps. I reinstalled the hose barb in the bottom using aquarium RTV silicone, and placed the bung with the bottle and pump in place to mimimize stressing the fitting. This bottle is slightly less tall than the old one also, so the tubing connecting it to the pump is longer and more flexible. I also elected to use a thinner wall tubing. I reinstalled everything and it looks promising. I hope it will just work.

As a side note- I was finally able to acquire the video taken three weeks ago when I did the final hook up and test drive in the car- I will be editing it shortly. I am working on loose ends, as well as the charging system. I am also trying to figure out exactly how I’m going to register it, I would like to have it be driveable as soon as possible!!

How to Charge Your EV’s AGM SLA Batteries

This is a work in progress- I am working on planning how the battery regulators for the car are going to work. One key part of that process is deciding on the actual optimal charging procedure for the Optima-type AGM battery.

One often-seen charging procedure is the “three-stage charging” process. It consists of three distinct phases:

- Bulk, constant current. The charger puts out its maximum possible current until the battery voltage reaches a certain setpoint (usually 14-15v for 12v nom. batteries.

- Absorption, constant voltage. The charger then holds the battery at that setpoint as the current declines, either for a certain amount of time or or until the current drops below a certain setpoint.

- Float, constant voltage/current. The battery voltage is kept at a lower voltage (usually around 13.8v) where there is little change in the current.

This process is recommended for its speed and efficiency. It would be reasonably possible to implement with the battery regulators.

The Optima documents specify a different regimen, however, for cyclic applications (applications like in the car where the batteries are cycled significantly, often- as opposed to starting or UPS use)

Cyclic Applications:

- 14.7 volts, no current limit as long as battery temperature remains below 125°F (51.7°C). When current falls below 1 amp, finish with 2 amp constant current for 1 hour.

This is a bit different, and a bit strange seeming. I found the Exide Orbital tech sheet a little more descriptive and useful to clarify and reinforce this different idea:

2. IUI or Constant Voltage/Constant Current/Constant Voltage Recharge: Appropriate for more continuous

cyclic discharge/recharge applications

o Step 1: Maximum current limit of 20% of nominal capacity (approx: 15 amps) and voltage limit of 14.4 volts (A)

o Step 2: Hold at 14.4 volts until recharge current reaches 2% of nominal capacity (1.5 amps for most Orbital sizes)

o Step 3: Hold current at 2% of nominal capacity (1.5 amps) for 2 hours

o Discontinue charge if battery reaches 50oC (122oF)

Taken from Exide Orbital Technical Information PDF

While the numbers Exide chose for the Orbital charging recommendations are a bit different, the concept is very much the same. It’s definitely useful to see this kind of consistancy.

So, how will this work?

- At first, all the regulators will not shunt, voltage will be under 14.7 volts at all batteries and current at all batteries will be the same, up to 20 amps (charger limit)

- As some batteries start to approach 14.7v the regulators will start regulating, up to their maximum shunt current, at which point the master regulator will start scaling back the charger current. Batteries that have not reached 14.7v yet will continue to charge at the lesser amperage. Charger current will continue to decrease to avoid pushing the strongest batteries over 14.7v.

- The charger output will go as low as 3.5 amps, since the regulators sink about 2.5 amps at wide open, that will allow the strongest batteries to reach 1 amp at 14.7v while the weaker ones continue to charge at up to 3.5 amps

- Once the strongest batteries have reached 1 amp at 14.7v the regulators can go into “extended absorbtion” phase for those batteries, with the charger still at 3.5 amp output can hold those batteries at 2 amp constant current for an hour, while the weaker batteries continue to do whatever they need to do.

- Once the strongest batteries have been charging at 2 amps for an hour, the charger will reduce to 2.5 amps to allow those batteries to stop charging entirely or 2 amps if all the other batteries have reached “extended absorption” phase. The regulators on those batteries that have completed an hour will shunt all the charge current.

- A low current float phase could be implemented after all batteries have completed an hour at 2 amps.

The individual regulators can be aware of the voltage of the battery they’re regulating and the current they’re sinking in the shunt by way of ohm’s law and the duty cycle the shunt is running at. The regulators must be able to be aware of the current the charger is putting out for a constant current mode. Temperature compensation capability would be desirable. The master charger regulator must be aware of the duty cycle of the regulators and the voltage they’re sensing to decide how to scale back the charge current. Alternately the regulators could ask the master to reduce current, although the latter setup could be less versatile.

I think that accounts for all the provisions laid out by the Optima charging specs, and this hardware setup. I’m sure I will continue to think about it and how it’s going to work though– of course!

In: Battery Regulator, EV Miata

A Tach for the Truck

Because my principal goal with this website is to post widely appreciable and useful content… here I bring you: How to install a ’60s Jaguar tachometer in a ’68 Dodge Sweptline 1/2 Ton Pickup.

Heh, all kidding aside, this is a little project I have thought about for a while, and it came together nicely. Let’s see:

The Jag tach has two wires of interest- a green wire attached to a faston terminal and a blue and white wire attached to a sort of banana plug thing. The green is +12v and the blue/white is the pulse signal. The metal body of the gauge must be attached to a solid vehicle ground. I used a small ring terminal to attach a wire to the tach body for ground. The signal wire must attach to the ignition coil, on the low voltage terminal that is attached to the distributor.

It worked on the first try!

Then- the small matter of attaching it to the dashboard, running wires for it, and attaching it to a power source that is only energized with the keyswitch on. It really needs a housing, to protect the wiring and exposed plastic on the rear of the gauge- remember, it’s british and almost 40 years old! For that, a tomato can turned out to be just the ticket.

Then- the small matter of attaching it to the dashboard, running wires for it, and attaching it to a power source that is only energized with the keyswitch on. It really needs a housing, to protect the wiring and exposed plastic on the rear of the gauge- remember, it’s british and almost 40 years old! For that, a tomato can turned out to be just the ticket.

I spliced +12v power into the radio power lead (already well-hacked and spliced), ran the signal lead out through the firewall to the coil, and wrapped the ground wire around one of the windshield wiper motor bolts (along with another unknown wire)

I spliced +12v power into the radio power lead (already well-hacked and spliced), ran the signal lead out through the firewall to the coil, and wrapped the ground wire around one of the windshield wiper motor bolts (along with another unknown wire)

Zip ties finish the installation. It’s beautiful.

This should work in any car with distributor and coil type ignition, and with most any tachometer, given that it came out of a car with the same number of cylinders as your target vehicle (this tach is from a Jag with inline 6, the dodge has the venerable 225 slant 6). Usually it is pretty easy to identify the +, – and signal connections to the tachometer gauge.

In: Big Blue Truck, Little Fixes

The Home Stretch

As you can tell from the last post- I’ve driven the Miata. I worked hard Friday and all weekend to make it come together for Sunday’s drive- while I edit the video from Sunday, I’ll post up my photos of the work I did to get ready- all the final wiring and mounting/integration–

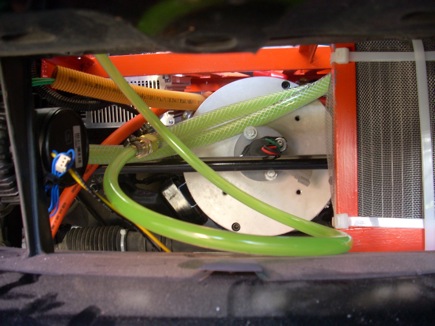

The first big challenge was figuring out how I was going to set up the water-cooling reservoir and pump for the Zilla controller- I had planned to use the OEM coolant overflow tank, adding taps to it using copper tubing and epoxy putty- I tested it and the epoxy putty failed immediately. (duh, it’s not magic… I was hoping it was magic) I realized the OEM reservoir really wasn’t going to be that good anyways, the hose routing was seriously iffy. So instead I thought to use a Nalgene water bottle- it ended up working very well. I hadn’t put anything far forward inside the bumper yet, this fit there without conflicting with anything else. I drilled and tapped (pipe tap) a hole in the bottom of the Nalgene bottle, then screwed in a 1/2 inch barb fitting and put some silicone on it. The bottle and pump are attached to a piece of 1/16″ aluminum (cut-off from the battery regulator base plates) which is riveted a bunch of times to the front bumper steel member. The top of the bottle fits through an already-present hole in the metal at the front of the engine bay, symmetrical to the windshield washer fluid filler hole.

Since then it has sprung a significant leak somewhere, I’ll need to investigate and apply silicone as needed- I’m still pleased at how it turned out. That pump, the Laing D4 is way plenty beefy for the application, it pushes plenty of fluid around, however is very quiet. The system gurgles but only because of the fluid splashing back into the reservoir. It will be nearly silent with a submerged return tube. The pump can not pump pure antifreeze, it is too viscous. I have diluted the antifreeze about 50/50 by my rough approximation, it seems to work fine now.

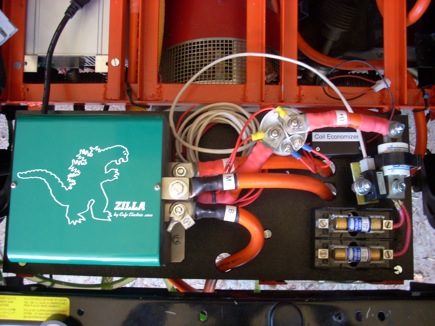

After avoiding it for weeks, I finally set about mounting and connecting the main power components-

The components are attached to 1/4 inch ABS. It is very easy to work with and strong, but slightly flexible. Dealing with those very short segments of welding cable is a serious pain… the cable is flexible enough, but when it the ends are crimped it fixes the strands in place and makes the bending behavior less predictable. The lead between the contactor and controller is most visibly distorted. Using solid copper machined bus-bars would definitely be nicer, as would having the various terminals at a more similar height. I ended up changing the position of the contactor mounting points slightly to relieve some stress, I was unable to get it back in place with the cables attached after I unbolted it.

Mounting the Hairball and working on the low-current wiring-

After float charging all the batteries and placing them in the car, doing all this wiring and fixing up the water cooling system I decided to head to bed a bit early Saturday night… Sunday was promising to be a big day, with Beth, Sean and Christian coming up from Santa Clara, a small list of additional things to be done, and the promise of driving the car.

I’m working on the video of the events on Sunday, and processing all the new stuff I now know about where I need to go with the project next- It’s not done yet, but I can say for sure that it is going to be awesome.

It Drove Today

New Business Cards

I made myself some business cards last night- meet me in person and I’ll give you one! They’re simply laser-printed on off-white 110# card stock. It’s not as heavy as typical business card stock, but I think it’s good enough.

In: Art and Design, Life and Times

Project FATE 300zx Back to its Old Self

That’s right folks, the Project FATE Nissan racecar fixed itself and is ready to go. Jonathan and I went to the Pick and Pull and thoroughly inspected the valvetrain construction of a 300zx there, based on that decided that the best first step to fixing ours was to let it run for a good while, that it would likely work out its problems.

(I would encourage you to click through to YouTube for the “HQ” version)

Now of course, while the engine was fixing itself it was also filling the neighborhood with noxious exhaust vapors- good times!

Can you smell it from there?

The 300zx valvetrain is seriously built tough! I was impressed! (This is the engine Jonathan and I dissected in the junkyard)

A rocker on its shaft, showing oil passages

Hydraulic lifters

Big springs, big cams

Close-up

After all day out at the junkyard and searching for steel for the trailer it was seriously uplifting to have the valve issues resolved. I am seriously looking forward to making our planned mods to the car now, and being able to bring it back for Arse-Freeze ’09!

Long day, job well done

More Phone Hackery

As I feared, the antenna support on my phone was not destined to last, it broke completely off shortly after the last post. What I did next is best shown through pictures:

The material is “JB Stick Weld” epoxy putty. So far it seems quite secure, reception is normal. I don’t want to risk breaking it again so I don’t plan on keeping it in my pocket all the time like before, but I think this fix will hold well.

The material is “JB Stick Weld” epoxy putty. So far it seems quite secure, reception is normal. I don’t want to risk breaking it again so I don’t plan on keeping it in my pocket all the time like before, but I think this fix will hold well.

It’s ugly, I know. I enjoy the feeling of having really made the phone uniquely mine by all this homespun repair work– it’s a tiny rebellion against throw-away culture.

Cell Ringer is GO

Several months ago when it became annoyingly clear that my 2 year old “Razr” phone was slowly dying I picked up a cheap out of contract Motorola E815 on eBay to replace it- I’ve been impressed with the phone, it gets excellent reception and battery life and I really enjoyed putting goofy MP3 ringtones on it after I did the SEEM hack to allow copying to and from removable memory.

I’ve had a couple of problems, though. First, I blew the ring speaker out. Seriously- the ringer was reduced to a nearly inaudible scratchy whisper. I think the mylar cone delaminated from the voice coil- probably while playing one of my more raucous ringtones. And- recently I noticed that the plastic case parts around the antenna have cracked. The antenna protrudes about an inch and gets plenty of abuse in my pocket- but it’s not designed with very good support. Now the antenna has some play in it.

Cut to the chase. I fixed the ringer, and I tried to superglue the case back together, but it broke again. If it gets worse I will make it a JB weld cast. About the ringer- I decided tonight to donate the old “Razr” to science:

I pulled its ringer speaker out, and decided to stick it in the E815. The speakers are not quite the same size, it’s not a drop-in fix.

I pulled its ringer speaker out, and decided to stick it in the E815. The speakers are not quite the same size, it’s not a drop-in fix.

(“Razr” speaker on the right, E815 mainboard, speaker contacts can be seen on the left side of the board, placed diagonally)

(“Razr” speaker on the right, E815 mainboard, speaker contacts can be seen on the left side of the board, placed diagonally)

I am impressed by the design of the E815, it’s simple and easy to pop it apart and back together, the FFC and connectors are robust and easy to use. I’m not so impressed with the antenna mounting at least it’s easy enough to take apart and put back together.

Since the “Razr” speaker doesn’t actually fit, I hot glued it to the circuit board and cut out some of the plastic bits that kept it from fitting in the bottom case. In doing so I busted one of the little clips off and had to re-solder it. Flux FTW.

It lives!

It lives!

Now I’ve got my speaker-phone back, and most importantly… my ringtones!

Looking a Lot Like an Electric Car