Twinkle Tag: An SMD Experiment- Part 1, Design

I’ve designed and had manufactured several PCBs over the last couple years for the Battery Regulator project. I’ve focused on using through-hole parts, using surface mount components infrequently only when necessary. Even after spending hours condensing the components and finding clever ways to rout traces to maximize the use of board- space I find the design rarely looks particularly dense or crammed. SMD parts to the rescue-

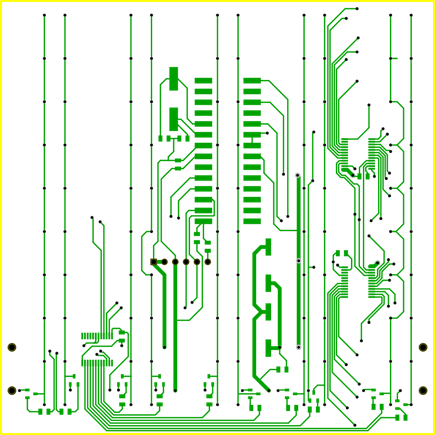

This project was conceived as a challenge, not out of necessity. I wondered if I could condense the circuitry required to drive a 10×10 RGB LED matrix (based on the EMSL Peggy 2 schematic) onto a small single two-sided circuit card, with no wasted space around the edges. This presented a couple challenges. I routed all the row circuitry horizontally on the front of the board, but since the row traces must be unbroken, all the column traces must be on the back of the board, attached via vias. This means the only space for support circuitry was between the ten column traces. Grouping the column traces in sets of two leaves four wider open strips, but only connectible to each other horizontally between the rows of LEDs on the front of the board. I was truly interested to see if it was possible to fit all the required connections or if I would run into insurmountable routing puzzles. About ten hours later I had drawn up all the footprints and traces- it looks like it’s not an impossible problem at all- it actually went together pretty elegantly.

Now the real question- to build it or not. I suppose the corillary to the “design a tricky high-density SMD based board” challenge is “assemble that tricky high-density SMD based board”. And of course, besides being a soldering challenge, it would be a pretty nifty little widget if it does in fact work. I’ve taken it as an opportunity to try out Sure Electronics‘s seriously cheap PCB fab service. (search eBay to find it) Depending on how long it actually takes to get these boards and their quality once they get here their service could be a really excellent bargain. Then it’ll be to Digi-Key for a bounty of 0805 passives, SOT-23 transistors and TSSOP-24 ICs. And to eBay for a bulk pack of “5050” or “PLCC-6” RGB LEDs.

We’ll see how well my fly-by-night land pattern artestry holds up to the real challenge of actually putting the thing together. Fortunately the ATmega 168/328 microcontroller will be a DIP300 package held in a standard socket with legs bent out and surface soldered- I decided a socketed mcu would probably be a good thing given that I didn’t add an ICSP header, only a FTDI style TTL serial header (SIL header fit between the rows of LEDs). Everything else is in a .025 pitch TSSOP package. We’ll see how it goes. I’m going for “learning experience” with this one. If it works that’ll be the icing on the cake.

And yes, I’m calling it the “Twinkle Tag”.