CNC Bike Headlight- Pt. 2

In between busy weeks at work and a week off in Ohio attending to family stuff I’ve been moving along with the bike headlight, making progress but coming home too tired to post anything. An update is in store.

First I finished running out the first operation on the “light body” part on the Hass SL10 CNC lathe.

I took a video of the cycle but I need to do some serious editing to it, mostly just looks like coolant splattering on the lens. There are good parts that are fun to watch, but mostly just a sea of blue foam.

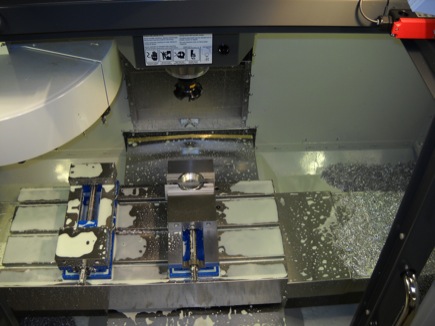

Next I was starting to feel unsure about the pace things were progressing at- feeling stalled and frustrated by my limited access to the community college shop during the summer- so I prevailed upon my supervisor/teacher at work who has a machine shop at home- he took home his favorite set of machines after owning a CNC machine shop for many years. He generously allowed me to come out to his place and work on the part in his machine- a Matsuura RA-IIF two pallet mill.

I spent most of the day prepping aluminum vise jaws, planning and programming, as well as familiarizing myself with Bob’s programming workflow and Yaznac machine control. The Matsuura, while not brand new has an extraordinarily high quality feel to it- tight, rigid, accurate- but somehow most strikingly quiet and smooth. I really enjoyed operating it and look forward to finishing out the light body piece on it in the next couple weeks.

Finally last week I was able to spend two nights at the community college where I turned my attention to the “nose ring” threaded lens-retainer that screws onto the front of the “light body”.

This part was made from the material left in the jaws of the lathe after turning the “light body”- the lathe spindle drawtube was too small to fit the stock, so each piece is left with a slug of material held in the chuck. I purposely bought oversize material for the light body so that that extra material could be used to make the “nose ring” pieces.

I set up for this part in one of the College’s two brand new Hass VF-2 3 axis mills, fully furnished with excellent brand new Sandvik tooling.

I like the new Hass machine also- the Hass control has a lot of really convenient user-friendly features, and the machines seem to be adequately rigid and powerful. They’ve certainly got a fast rapid speed, for such a small travel machine! I’m not a big fan of the carousel style toolchanger, particularly without a chip conveyor- it is dangerous to scoop chips out of the machine with that array of razor sharp tools just above your head. I thread milled the ID thread inside the “nose ring” using a Coromill 327 interchangable-insert grooving and threading tool, which did an awesome job- finish is excellent. It’s a pretty spiffy tool.

I ordered all the endmills I’ll need to finish out the Lightbody part- then it’s just running them and the “nose rings” out, and making a couple other parts. I have been working on redesigning the handlebar mounting scheme to use a rubber O-ring as a elastic strap, like many commercial bikelights do- ditching my previous plan with the ball-and-socket system. I’ve also been thinking about slightly tweaking the “nose ring” design so that an oring can be placed in the thread relief groove in the light body and interface with a smooth diameter on the “nose ring” to give enough friction at the end of the thread to prevent the ring from working loose with vibration, similar to the way the O-rings are used on mag-lights and many other flashlights. I just need to dial in that diameter, and maybe add a more generous chamfer to help the O-ring seat.

Spendy stash of solid carbide tooling. I shouldn’t have bought multiples of everything- it’s aluminum… it’s pretty unlikely I’m going to break a tool, and no chance I’ll wear one out in 20 parts… but I’ve gotten used to buying extras for work.

Sweet MA Ford 3 Flute .250 diameter, 1.125 LOC Aluminum cutting endmill- just right for cutting out the fins in the back of the light-body.