More CNC Thoughts

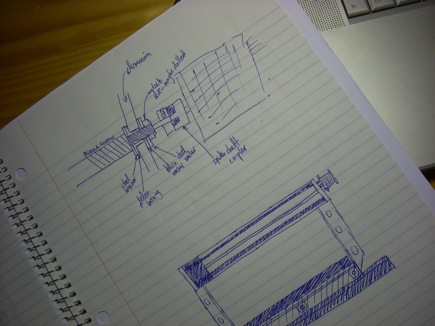

I’ve been thinking more about how I would I’m going to build a CNC mill. My earlier ideas have changed a bit, some a lot.

I’m not going to try to use servos, it is worth more to me to get the machine usable quickly, and the HobbyCNC stepper boards are pretty nice. It would also be an easy upgrade to hook it up to the step/direction signals from the KCam MaxStepper or DeskCNC board. These seem all like nicely developed, reasonably priced and reasonably effective solutions. I plan to use a big Chinese switchmode powersupply to power the HobbyCNC driver board, rather than the transformer/bridge setup they describe in the kits. You can pick them up for dirt cheap, and they are very easy to use.

I would still like to use a “CNC on a Budget” Z axis, I’m going to inquire about getting one of those, hopefully soon so I can use its design as inspiration for the other axes. I am pretty sure I want a gantry Y axis setup, but further than that, I’m really not so sure. I suppose I should probably start I just spent some time looking around at other’s machines on Google and CNCZone- it looks like bunches of people do the gantry arrangement with dual leadscrews at either side of the X axis (that moves the gantry up and down the table) I suppose that wouldn’t be too bad, just have to get a hold of some timing belt and pulleys. Then you really do have to have good thrust support bearings on the leadscrews also, since there won’t be any other thrust support from a directly connected motor- though I would avoid relying on that anyhow. I guess then I should continue shopping the eBay- see if any good deals come up on rails and trucks or rods and bearings. I think either would work fine. I like the idea of not having any important parts under the cutting table- I think it could increase the versitility of the mill greatly in some situations to be able to set it up on any sort of table material.

I found this site today and read through a bunch of their (excellent) content. Makes me think that using a single speed Porter Cable router, a variac, and their fancy chucks would make a pretty good spindle. There’s also lots of great info on there about bits in general and how to best use them.

I should probably hop on Sketchup again… see if I like it any better than I did last time I tried it. Or maybe I’ll test out SolidWorks. I’m in a class about AutoCAD right now, but I rather detest it- maybe I’ll draw this up in one of the aformentioned programs and then draw it in AutoCAD for my class project.

Anything’s better than just napkin sketches.

on June 8, 2010 at 8:38 am

·